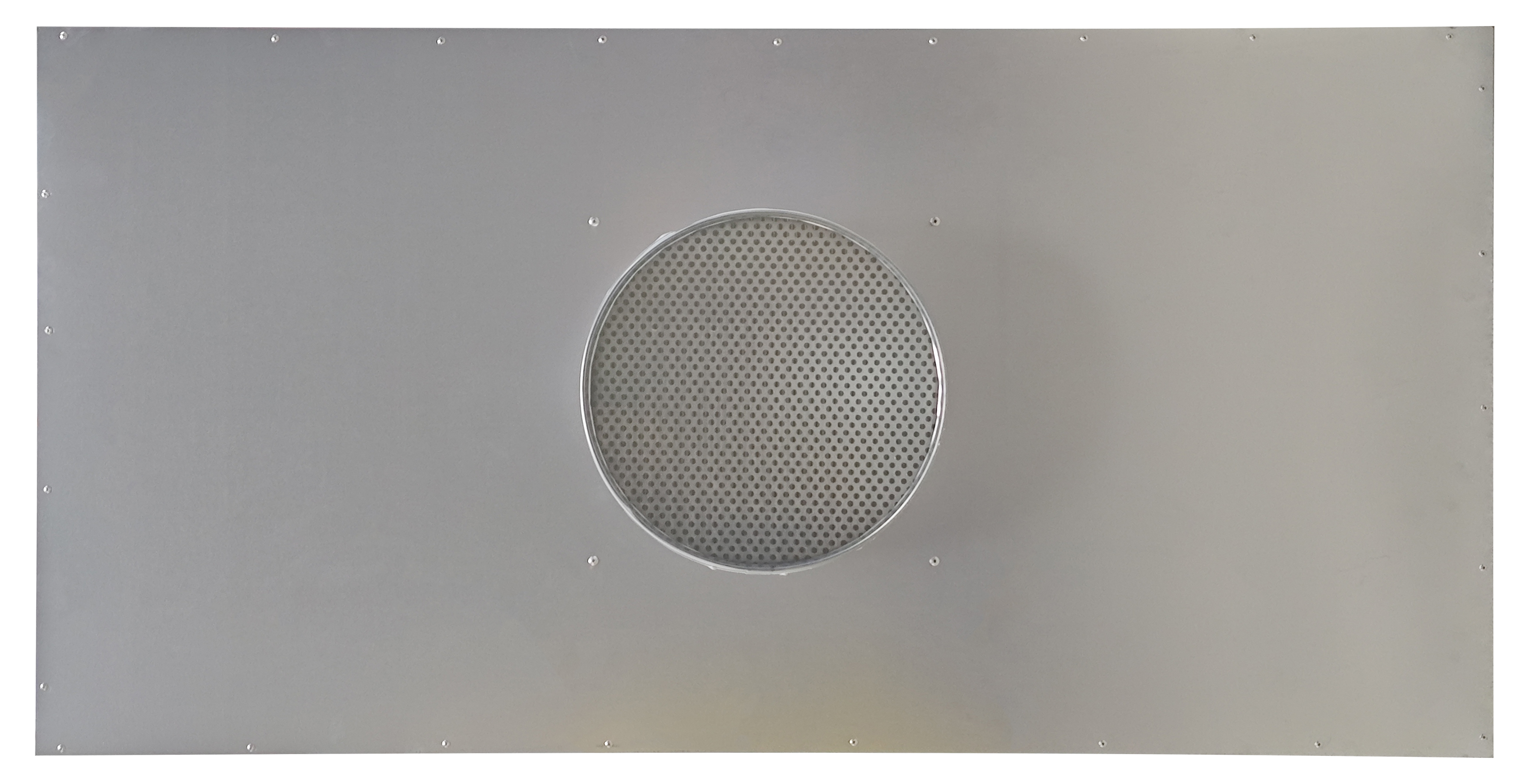

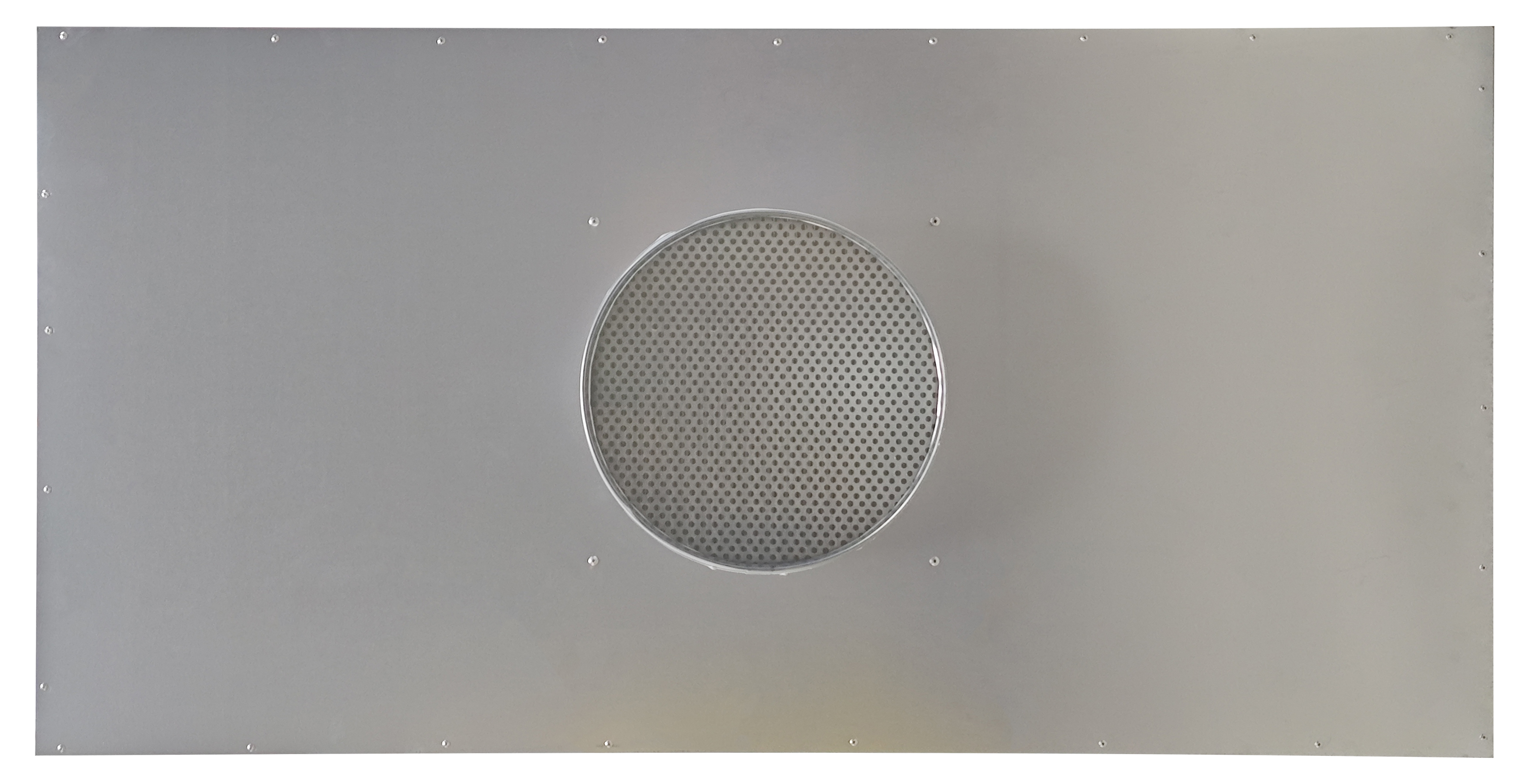

It consists of a static pressure box and a non-partition high-efficiency filter, integrated into one. This design avoids the leak testing of filters during on-site installation, reduces construction risks, and simultaneously makes the installation more convenient and rapid, effectively shortening the construction period. A closed structure is adopted, and leakage between the air inlet and outlet is prevented through testing. Both the casing and end covers are well-sealed to avoid lateral leakage.

Application:

I. Medical Field

1. Hospital Operating Rooms: Maintain a sterile environment to prevent microbial transmission through the air and infect patients. The integrated design facilitates installation and replacement.

2. Hospital Wards: Provide clean air for patients with compromised immune systems, ensuring good indoor ventilation with low-resistance characteristics.

3. Hospital Laboratories: Purify the air to protect laboratory personnel from harmful gases and particulate leakage.

II. Electronics Industry

1. Semiconductor Manufacturing Workshops: Filter out minute particles to ensure a high degree of cleanliness in production workshops, enhancing the yield of quality chips.

2. Electronic Equipment Assembly Workshops: Reduce the impact of dust on electronic components and lower the risk of static electricity accumulation.

3. Data Center Engineer Rooms: Prevent dust and other impurities from affecting server heat dissipation and operation. Single-use design facilitates management.

III. Food and Beverage Industry

1. Food Processing Workshops: Intercept impurities and microorganisms in the air to ensure hygienic food production.

2. Beverage Bottling Workshops: Prevent foreign objects in the air from entering beverages, ensuring product quality and safety.

IV. Pharmaceutical Industry

High cleanliness air is required in all aspects of pharmaceutical production. This filter can effectively remove contaminants and comply with GMP standards.