Enkonduko:

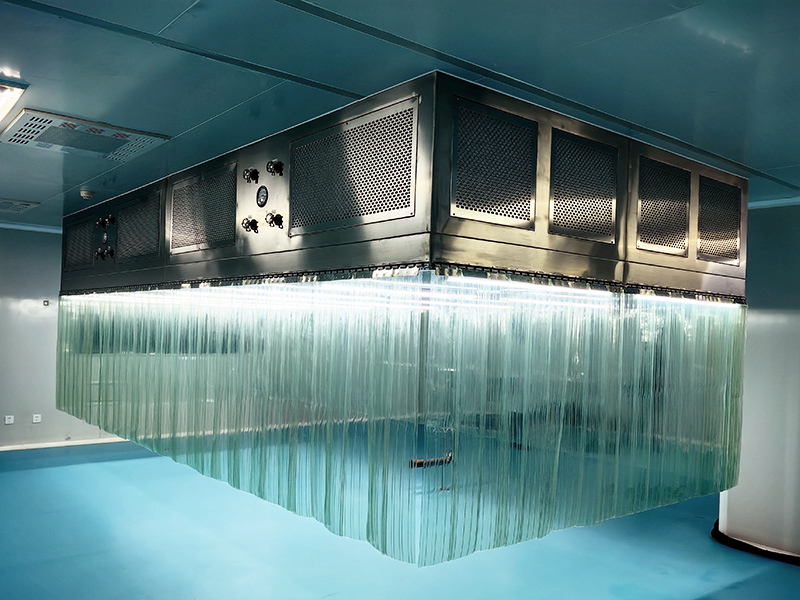

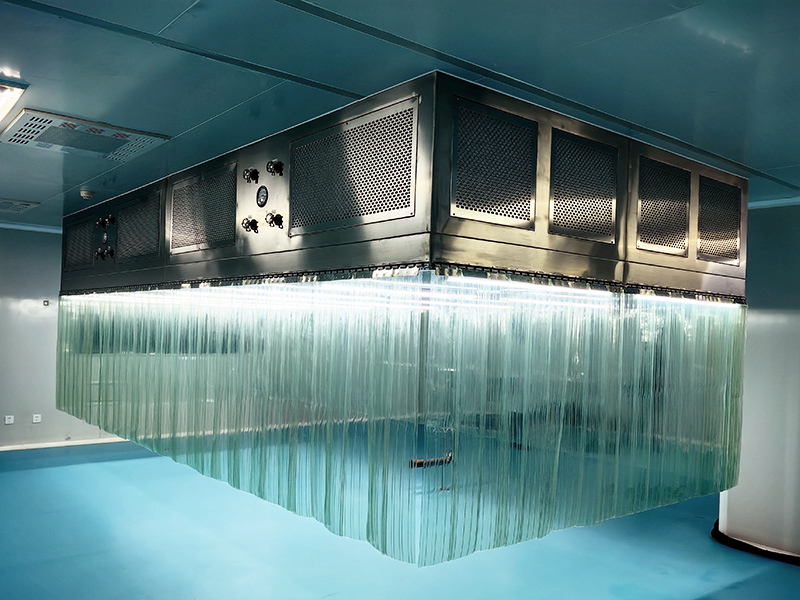

The Clean Laminar Flow Hood (Laminar Flow Hood, Down Flow) is a vertical unidirectional flow purification device constructed with a SUS304 stainless steel casing, high-efficiency filters, and variable frequency speed-adjustable fans. It ensures a constant wind speed of 0.45m/s through real-time monitoring of wind speed and pressure differential, capable of creating a Class A sterile environment within Grade C/B pharmaceutical industry settings, and offers options for ceiling-mounted or bracket-mounted installation, as well as perforated plate or airflow equalizing membrane air supply methods.

Application:

Medical: Operating rooms, ICU wards, aseptic drug filling – reducing infection risks.

Electronics manufacturing: Semiconductor lithography, precision instrument assembly – preventing dust contamination-induced short circuits.

Biopharmaceuticals: Raw material weighing, cell culture – ensuring sterile environments.

Food & chemical industries: Aseptic packaging, explosion-proof workshops – controlling microbial growth and hazardous gases.