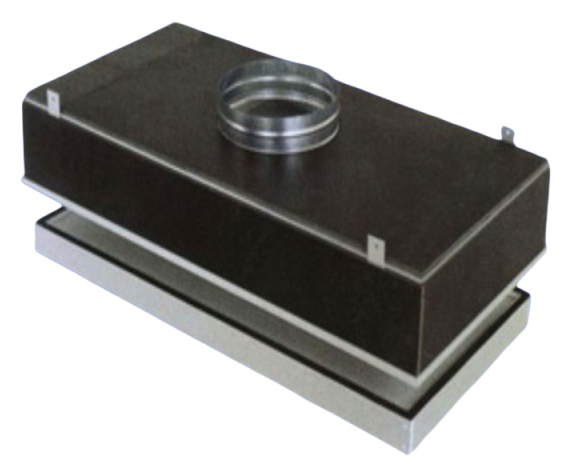

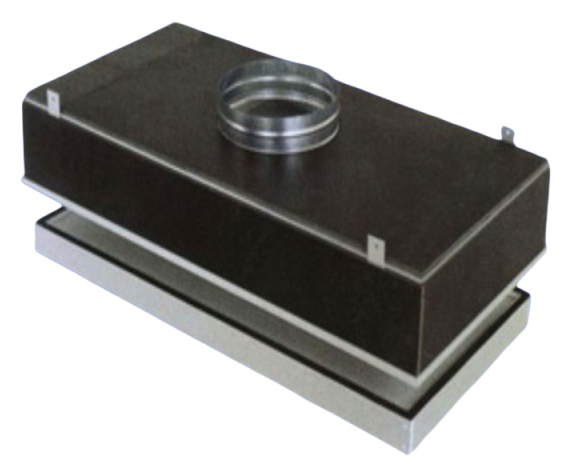

The system adopts a split-type structure, typically composed of an outer frame (plenum), filter cartridge, and sealing cover. The filter cartridge is detachable from the housing, enabling replacement of the cartridge alone without disassembling the entire unit, thereby reducing maintenance costs. The core filtration material is a non-separator HEPA filter, utilizing ultra-fine glass fiber as the filter medium, with a filtration efficiency of H10 to U17 grades (as per EN 1822/ISO 29463 standards), achieving ≥99.97% efficiency for 0.3μm particles.

Application:

Medical & Cleanroom Industries

Used in hospital operating rooms, pharmaceutical cleanrooms, microelectronics factories, and other controlled environments to ensure air quality meets ISO Class 5 (Class 100) cleanliness standards, effectively preventing microbial and particulate contamination.

Automotive & Mechanical Equipment

Automotive engine air filters feature a snap-fit design for rapid replacement, preventing dust ingress into cylinders to reduce mechanical wear. Replacement is recommended every 15,000 kilometers.

Compressed Air Systems

In industrial compressed air systems, precision filter cartridges (e.g., DOMNICK HUNTER system’s AX-grade filters capable of removing 0.01μm oil aerosols) are selected on-demand to safeguard sensitive instruments or medical respiratory equipment.